Omega Pilzno, one of the largest companies in the transport and logistics industry, asked us to create a comprehensive and dedicated TMS (transport management system) for their needs, as well as an application for drivers to manage transport, transfer orders and communicate with drivers.

Objective:

Creating a comprehensive TMS solution to meet the customer’s requirements. The available off-the-shelf solutions on the market did not meet the requirements of such a large company and limited the further development of business. Therefore, the decision was made to create a dedicated solution, tailored to the needs and requirements of both the business and forwarding, planning departments. The priority was to ensure the efficiency and reliability of the system, which would enable effective management of Omega Pilzno’s transportation.

Challenge:

The challenge for us was to create a comprehensive TMS that would allow us to continuously monitor and manage over 300,000 orders, more than 2,000 trucks and few thousand users. This required not only developing a new solution, but also conducting a successful migration from an outdated TMS.

The project team focused on designing a new, more efficient system that enabled automation of shippers’ work and optimization of transportation costs. The migration carried out was a key element in the project’s success, as it enabled a safe and efficient system change without data loss or interruption.

Activities:

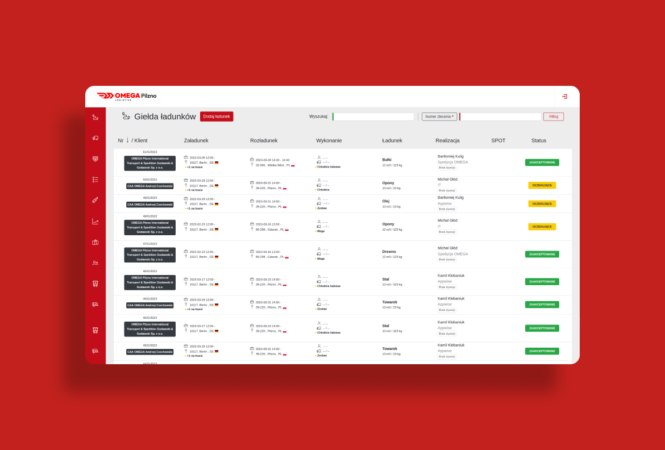

As part of a project for Omega Pilzno, we implemented a comprehensive TMS system tailored to the needs of such a large organization. When designing the system, great importance was placed on speed of operation, minimum number of manual operations, and automating everything that can be automated. The map solution was based on integration with PTV maps dedicated to freight transport. which enabled efficient and accurate routing, as well as real-time tracking of the vehicle fleet.

PTV Maps is an advanced geolocation tool that allows you to pinpoint the location of vehicles, plan a route, and indicate the optimal route.

Together with the team, we also built an application for drivers to collect points for completed orders. This was an incentive component for drivers, while also allowing them to monitor their work progress.

Our advanced algorithms have automated the work of shippers and made it possible to lay out the best route, resulting in optimization of route costs, fuel and labor time.

Conclusions:

A key component of the project was the TMS system, which allows Omega Pilzno employees to continuously monitor and manage orders. The system also provided the ability to analyze and optimize transportation costs, resulting in higher profits for the customer. By migrating from an outdated TMS to our new solution, Omega Pilzno gained a more effective and efficient system that made work much easier and allowed the company to achieve more